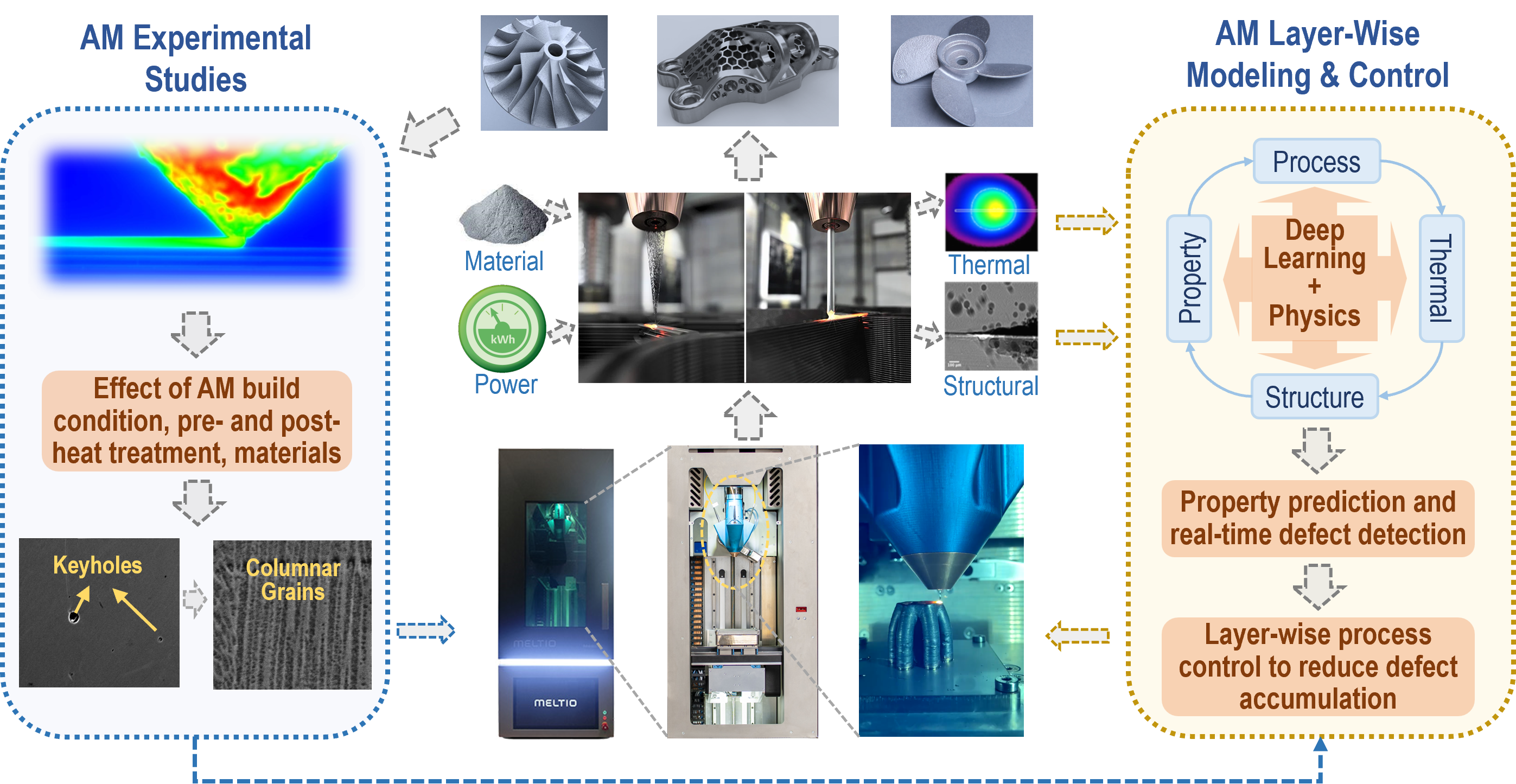

Investigating the relationships between process variables and resource consumption and product quality in a production line is critical to optimizing the processes and improving manufacturing, energy, and material efficiency as well as product quality. This research will investigate recent advancements in data science (e.g., Bayesian inference and deep learning) and develop manufacturing-specific machine learning algorithms for better characterization of process dynamics and in-situ detection of defects, towards efficiency and quality improvement.

One part of the research focuses on establishing the process-structure-property-performance (PSPP) relationships for complex manufacturing processes (e.g., metal additive manufacturing processes). To improve the credibility of multi-domain and heterogeneous modeling, physical domain knowledge is integrated into the model structure and training. The other part of the research includes the design of proper sensing and efficient data process pipelines for in-situ defect (surface and internal defects) detection, followed by adaptive process control to reduce defect accumulation and ensure fabrication quality.